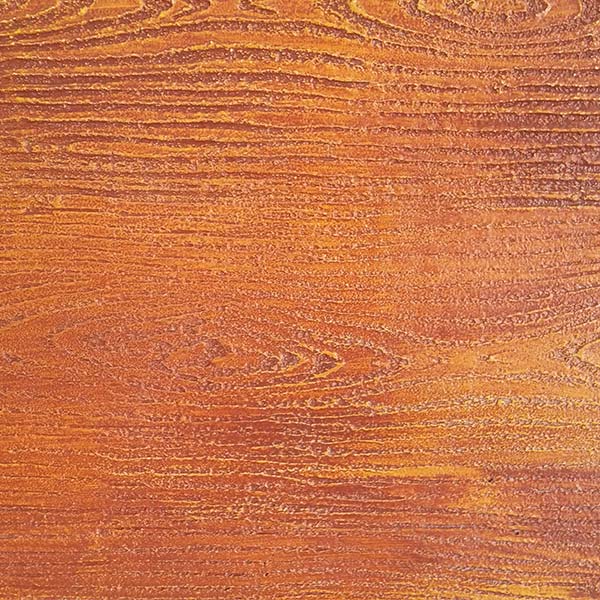

DECO COAT - WOOD

DESCRIPTION

It is cement based, high strength, special additive, silicon and micro fiber reinforced, wooden patterned decorative mineral facade covering.

FEATURES

It has high water vapor permeability. It allows the buildings to breathe. It is resistant to external factors thanks to special additives. It is waterproof. It is a natural and decorative appearance. Easy to apply. Can be painted with exterior paint.

TECHNICIAL SPECIFIATIONS

| View | Gray, White Color |

| Mixing Ratio | 5.5-6 lt water /25 kg |

| Grain size | 3 mm |

| Consumption Amount | 12 - 13 kg/m2 (For 1 cm thickness) |

| Application Temperature | Between +5 ° C and +35 ° C |

| Capillary Water Absorption | 0.3 kg/m2 .h0.5 ( W1) |

| Fire Response Class | A1 |

| Pressure Resistance | > 3.5 N/mm2 ( CS III ) |

| Dry Mortar Density | 1550 ± 100 kg/m2 |

| Bending Strength | > 1 N/mm2 |

| Water Vapor Transmission | 25 µ |

• The above values are valid for +23 oC temperature and 50% relative humidity. The time is shortened at high temperatures and the time is extended at low temperatures.

UGAGE AREAS

It is used as the final layer coating material on the exterior facades and exterior heat insulation systems in the cement based cisterns of all buildings.

BENEFITS

Easy to prepare and apply. Operation is ready. It provides high adherence to concrete and plastered surfaces. It is resistant to water and frost. It is not affected by temperature differences.

INSTRUCTIONS FOR USE

Dust, swollen strata, dirt, oil, etc. in places where application is to be made. materials must be cleaned from the surface. The surface must be clean, properly solid. Before application, the surface must be saturated with water in very hot and windy weather. 25 kg of STUCCO TURCO, DEKO COAT - WOOD should be mixed with 6-6.5 lt clean water on average with the help of low speed mixer until a homogeneous consistency is achieved. The mortar should be rested for 5 minutes before application and then mixed again. With STUCCO TURCO, DEKO COAT - WOOD stainless steel trowel, the application thickness should be adjusted according to the largest pattern stone. The surface must be patterned with circular movements with plastic trowel. Designing should always be done with the mortar being wet. Percentage can not be left as final layer material. It is absolutely necessary to paint it after drying. When preparing the mortar, the recommended water content and rest periods must be observed. Application under direct sun should be avoided. Previously prepared hardened materials should not be included in newly prepared mortar. Do not apply above 35 ° C below + 5 ° C. It should not be applied on surfaces that are too humid and / or frosted in hot weather or that are dangerous to frost within 24 hours.

Note: Foreign material such as lime, cement, plaster, sand should not be added to the prepared plaster.

PACKING

25 kg PE reinforced kraft bag

A palette (110x110 cm) with 64 bags.

STORAGE AND SHELF LIFE

Maximum 2 pallets should be placed on the unopened original packaging in a cool and dry environment. The shelf life is 12 months from the date of production under suitable storage conditions.

SECURITY PRECAUTIONS

Protective gloves, protective gloves, goggles and masks should be used during the application. Due to the irritant effects of uncured material, it should be washed immediately with plenty of water and soap in case of contact with skin and pond. If swallowed, seek medical advice immediately. Food and drink materials should not be put into the application areas. It should be stored at places where children can not reach it.

RESPONSIBILITY

Our company is not responsible for any application errors that may occur if the product is not used for its intended purpose or if the above technical application conditions and suggestions are not followed. The notes on this technique include the information on the date they are written. The manufacturer reserves the right to change them.

It is suitable to TS 7847 standard.